Marking/ Labeling Requirements

All labels must show the following:

-

- Shipper’s name and address

- Consignee’s name and address

- NASSCO’s purchase order number

- Carton number (e.g., 1 of 5, etc.)

- Packing list number/NASSCO part number/quantity

- Weight

A packing list shall accompany each shipment. It shall be securely attached to the outside of the #1 container and protected against accidental removal or damage. (Containers with dimensions under 12”x12”x12” are exempt from this requirement. Instead, the packing list may be placed within the container). The packing list shall contain the following:

-

- Packing slip number

- The NASSCO purchase order number

- The purchase order line item number

- Release number, if applicable

- Quantity shipped

- Unit of measure

- Supplier's name

- NASSCO's part number(s) if applicable, description of item(s) including the revision index and engineering order (if applicable) of the supplier’s part number.

- Serial number (if applicable)

- The batch lot, compound number and/or manufacturer, assembly, cure date, and shelf life limitations when such information is required to be entered on the part and/or on its container.

- Rejection Notice SASO/DMT number where applicable.

- BFE (Buyer Furnished Equipment) that is serialized shall have the serial number referenced on the packing slip of the assembly being shipped to Gulfstream. Barcodes are required for BFE serialized parts.

Shipments of tubing and extrusions are to plainly indicate total footage on each container.

All material shipped for testing or experimental purposes must be clearly marked on interior and exterior containers, “NOT FOR PRODUCTION – EXPERIMENTAL OR TEST MATERIAL”. The name and telephone number of the individual who is to receive the consignment must be entered on the Bill of Lading and on all other documents.

For repaired parts, a repair/teardown report shall be attached to the part or packing list. It should state what action took place (repaired or overhauled) and what parts were replaced. When applicable, it shall also indicate time since new.

Any additional data specified in the Purchase Order, Release, and Rejection Notice or elsewhere in these instructions.

Wood packaging

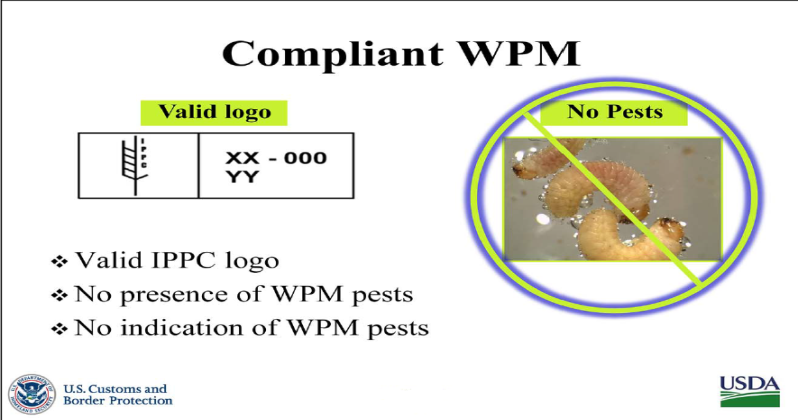

Requirements for Wood Packaging Material (WPM) Imports

This standard describes phyto-sanitary measures that reduce the risk of introduction and spread of quarantine pests associated with the movement in international trade of wood packaging material made from raw wood. Wood packaging material covered by this standard includes dunnage but excludes wood packaging made from wood processed in such a way that it is free from pests (e.g. plywood).

2. Approved phytosanitary measures that significantly reduce the risk of pest introduction and spread via wood packaging material consist of the use of debarked wood (with a specified tolerance for remaining bark) and the application of approved treatments (as prescribed in Annex 1). The application of the recognized mark (as prescribed in Annex 2) ensures that wood packaging material subjected to the approved treatments is readily identifiable. The approved treatments, the mark and its use are described. ISPM 15 is the International Standards for Phytosanitary Measures Publication No. 15- Guidelines for Regulating Wood Packaging in International Trade. It represents the first international commodity based standard and sets out criteria for regulating wood packaging material used in international trade.

Reference for Wood Packaging Material (WPM) from USCBP and USDA: http://www.cbp.gov/linkhandler/cgov/trade/trade_outreach/wood_packaging_pp.ctt/wood_packaging_pp.pdf